Are you ready to uncover the strategies that set the top 10% of bakeries apart from the rest? Our exclusive ebook is your ultimate guide to thriving in the competitive hospitality industry.

Inside, you'll discover tips, proven techniques, and real-world case studies that reveal the secrets of successful bakeries. From effective marketing strategies to operational efficiency hacks, this ebook covers it all.

Know How 10% Bakeries Survive & Succeed?

Download E-Book

Serving 50,000+ Entrepreneurs

How We Help Bakeries?

How it Works?

Embark on your growth journey with confidence! Simply make an enquiry, and our dedicated in-house experts will be in touch to kickstart your bakery's success story.

Don't wait any longer – take the first step towards achieving your business goals today!

- Make An Enquiry

- Our In-House Experts will get in Touch with You

- Your Growth journey begins!

Bakery’s Life Cycle

Without Expert

With Expert!

- Limited understanding of Ideal Location Criteria, Potential Risks & Market Analysis

- Lack of expertise in kitchen layout design, workflow optimisation resulting in inefficient operations

- Limited knowledge of equipment, leading to subpar equipment choices, potential breakdowns, and higher AMC costs.

- Difficulty in managing and maintaining kitchen equipment, lack of regular servicing and upkeep

- In-depth analysis of Location Suitability, Market Trends, Competition Assessment & Strategic Recommendations

- An Efficient Kitchen Layout, Selecting the Right Equipment, Optimised Workflow for Better Productivity

- Durable, efficient, and appropriate commercial kitchen equipment tailored to specific needs

- Regular maintenance, timely repairs, spare parts availability, and technical support

Bakery’s Life Cycle

Without Expert

- Limited understanding of Ideal Location Criteria, Potential Risks & Market Analysis

- Lack of expertise in kitchen layout design, workflow optimisation resulting in inefficient operations

- Limited knowledge of equipment, leading to subpar equipment choices, potential breakdowns, and higher AMC costs.

- Difficulty in managing and maintaining kitchen equipment, lack of regular servicing and upkeep

With Expert!

- In-depth analysis of Location Suitability, Market Trends, Competition Assessment & Strategic Recommendations

- An Efficient Kitchen Layout, Selecting the Right Equipment, Optimised Workflow for Better Productivity

- Durable, efficient, and appropriate commercial kitchen equipment tailored to specific needs

- Regular maintenance, timely repairs, spare parts availability, and technical support

FAQs

Answer: A location survey report provides insights into foot traffic patterns, demographics, competitor analysis, and market trends specific to bakery products. It helps you choose a strategic location with high customer demand and minimal competition, maximizing your bakery's potential for success.

Designing an efficient bakery kitchen layout involves factors such as workflow optimization, proper equipment placement, adequate workspace for pastry preparation, temperature control for dough proofing and baking, storage solutions for ingredients, and compliance with hygiene standards. A consultancy service can guide you in creating a functional and productive bakery kitchen.

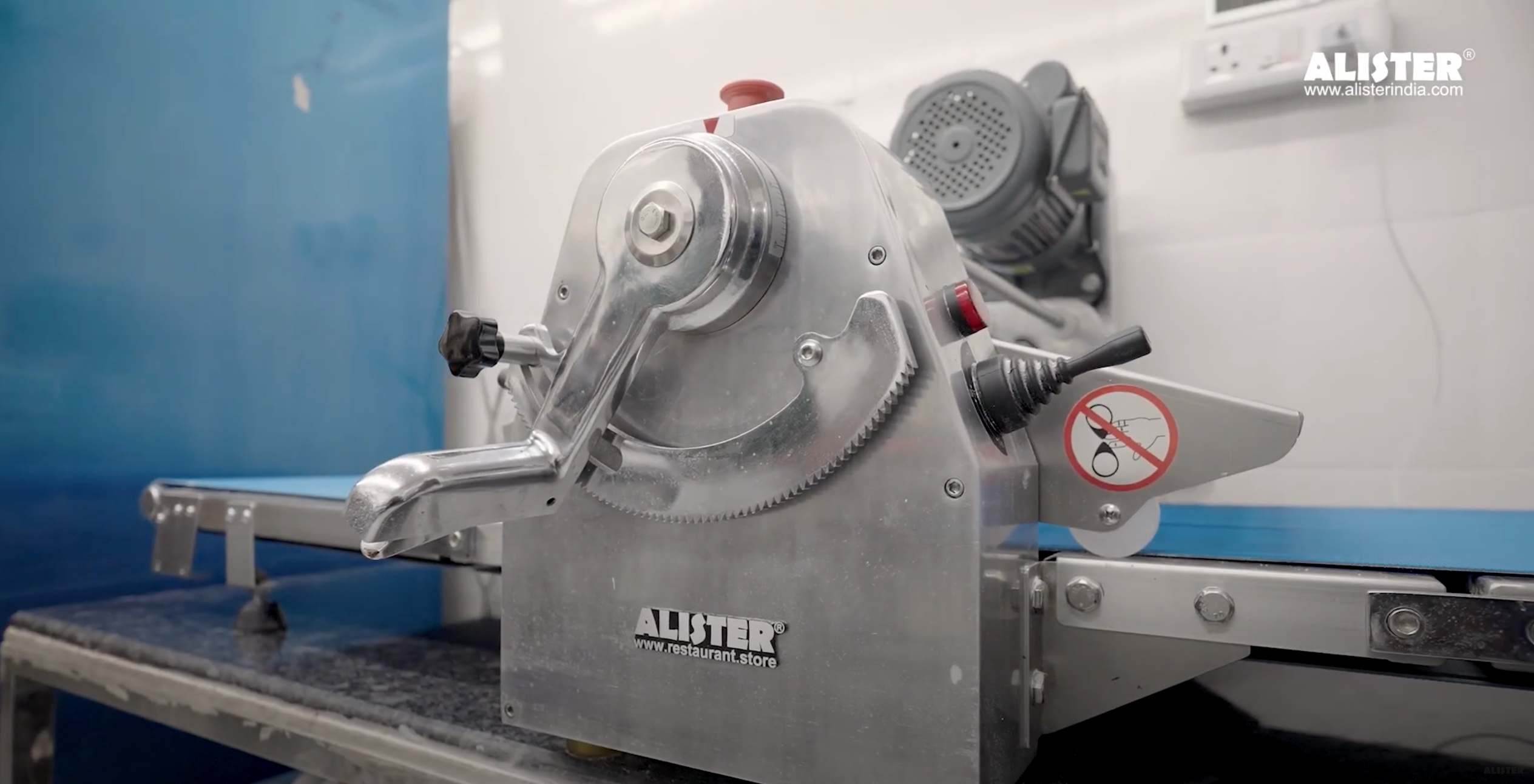

Essential commercial kitchen equipment for a bakery includes ovens (convection, deck, and rotary), dough mixers, proofing cabinets, refrigerators, freezers, dough sheeters, bread slicers, and display cases. These equipment items are crucial for efficient baking operations and showcasing bakery products to customers.

An AMC ensures regular maintenance, cleaning, and servicing of bakery equipment such as ovens, mixers, and refrigeration units. This proactive approach minimizes downtime, prevents equipment breakdowns during peak production periods, extends equipment lifespan, and reduces repair costs. It also ensures that bakery operations run smoothly and efficiently.