Take AMC only if.....

You Want To Prevent Breakdowns Which Can Halt Your Business

You Want To Decrease Repair & Replacement Cost

You Want To Be Consistent In Service Quality & Customer Satisfaction

You Want To Avoid Non-Compliance Which Can Lead To Legal Troubles

Prevent Downtime & Production Disruptions

- Unmaintained ovens, mixers, and refrigeration units can suddenly stop working.

- Unexpected failures can halt production, leading to lost sales and unhappy customers.

- Emergency repairs can be expensive and disrupt daily operations.

- Scheduled maintenance ensures continuous workflow and steady production.

Save on Expensive Repairs & Replacements

- Routine maintenance prevents small issues from escalating into major problems.

- Extends the lifespan of essential bakery equipment, reducing replacement costs.

- Helps avoid surprise repair expenses that can strain business finances.

- Keeps your bakery running cost-effectively in the long run.

Hassle-Free Operations & Peace of Mind

- AMC providers handle scheduled maintenance, so you can focus on your business.

- Keeps bakery equipment in optimal condition, reducing unexpected breakdowns.

- Eliminates last-minute stress related to sudden repairs and downtime.

- Provides expert technical support and fast issue resolution.

FAQs

Answer: A location survey report provides insights into foot traffic patterns, demographics, competitor analysis, and market trends specific to bakery products. It helps you choose a strategic location with high customer demand and minimal competition, maximizing your bakery's potential for success.

Designing an efficient bakery kitchen layout involves factors such as workflow optimization, proper equipment placement, adequate workspace for pastry preparation, temperature control for dough proofing and baking, storage solutions for ingredients, and compliance with hygiene standards. A consultancy service can guide you in creating a functional and productive bakery kitchen.

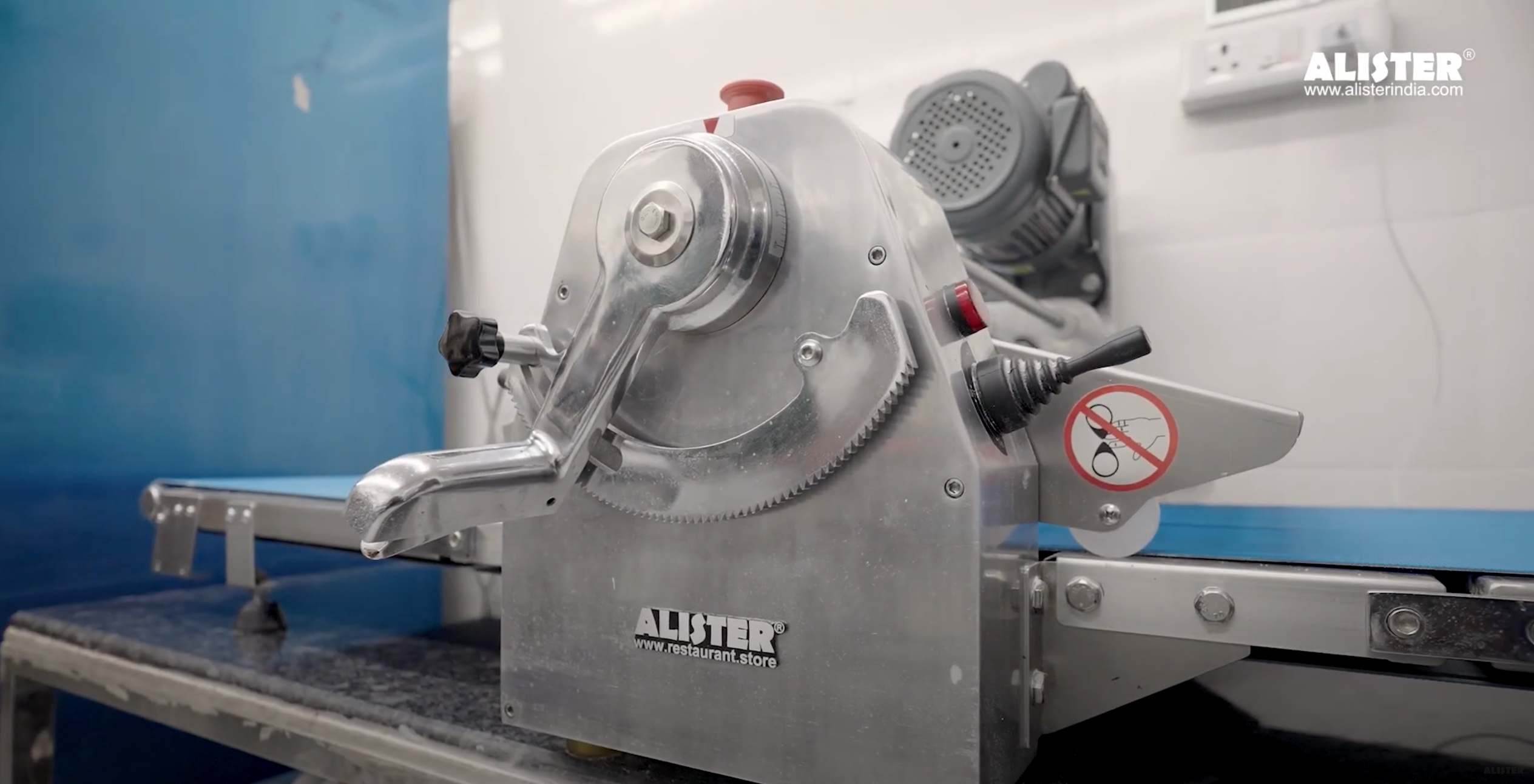

Essential commercial kitchen equipment for a bakery includes ovens (convection, deck, and rotary), dough mixers, proofing cabinets, refrigerators, freezers, dough sheeters, bread slicers, and display cases. These equipment items are crucial for efficient baking operations and showcasing bakery products to customers.

An AMC ensures regular maintenance, cleaning, and servicing of bakery equipment such as ovens, mixers, and refrigeration units. This proactive approach minimizes downtime, prevents equipment breakdowns during peak production periods, extends equipment lifespan, and reduces repair costs. It also ensures that bakery operations run smoothly and efficiently.